The Not-So-Green Side of Solar

Sancho Cagulada | December 26, 2019

Solar panels are growing in popularity as nations around the world are becoming aware of their significant contribution in fighting climate change. In terms of sustainability, solar energy is more appealing than conventional fossil fuels since it is a clean, accessible, and a non-depleting energy source. According to IBISWorld, solar panel manufacturing’s annual revenue soared by 66% from $360M to $430M between 2017 and 2019. This growth is due to decreasing prices along with government subsidies, tax credits, and other incentives. Furthermore, the U.S. Energy Information Administration stated that generated electricity from solar panels skyrocketed from 510M kilowatt-hours (kWh) to 16B kWh. This makes solar power the fastest growing electricity generation source in the United States.

As a relatively new technology in comparison to conventional fossil fuels, some questions arise in terms of its environmental impacts. As we see the trend of significant demand increase, is the industry ready to support much bigger consumer populations while not posing harm to our environment? Industries inevitably create environmental impacts, and solar panel manufacturing is no exception. To better understand how solar panels impact the environment, we must consider their manufacturing process.

Manufacturing Solar Panels

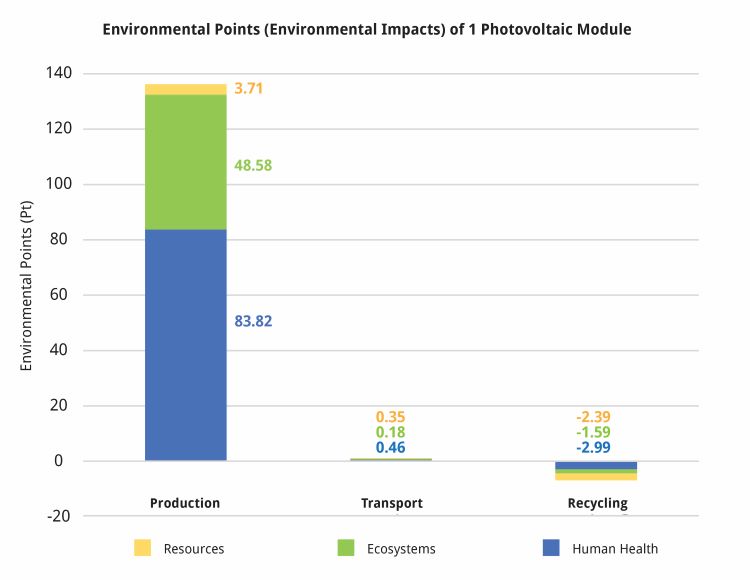

While each phase of creating solar panels constitutes specific environmental impacts, the production process has the largest impact, as outlined in a study conducted by Silesian University of Technology in Poland. The graph below shows the impact of one photovoltaic (PV) module (one solar panel can consist of one or more PV modules) during production, transport and recycling. But what are its specific environmental impacts?

Waste Management Vol. 70, pp. 198-203.

Production starts with gathering the needed materials. Quartz is the starting material for solar panel production and acquiring it is generally not a sustainable process. It is usually extracted through mining, specifically land blasting. The Environmental Protection Agency (EPA) stated in their environmental impact report that land blasting, one of the methods used in mining quartz, has several environmental implications. First, due to usage of explosives, mining operations emit particulate matter that can contaminate air. This can include arsenic, lead, and other toxic heavy metals. If inhaled, it can cause various respiratory diseases. One example is silicosis – a lung disease caused by inhalation of crystalline silicon dioxide. EPA also stated that land blasting significantly disrupts wildlife habitats and other natural systems by decreasing groundwater recharge, lowering the water table, altering the land topography, contaminating habitats with chemicals, and land subsidence.

Once mined, quartz undergoes several refinements to acquire polysilicon – the key material in harnessing energy from the sun through solar panels. Acquiring silicon creates by-products and wastes that are hazardous and toxic. If not disposed and managed properly, it can cause issues related to the environment and public health. Silicon tetrachloride for example, is used to refine silicon into polysilicon. According to the U.S. National Library of Medicine, exposure to its vapor can cause difficulty in breathing, and irritation to eyes, nose, and throat.

A study from Nanyang Technological University in Singapore, identified a variety of hazardous materials are used during the production of solar panels. While these materials are well controlled and monitored, accidental exposure and leakages can occur. Their study stated that primary health concerns of silicon-based panels could potentially affect manufacturing workers, nearby residents and wildlife via inhalation of toxic gases and fumes. This risk is reinforced by the Union of Concerned Scientists, who say that solar panel workers are facing risks of inhaling silicon dust during the process of cleaning silicon wafers.

Leakages can also contaminate waterways. In 2011, Jinko Solar Holding Corporation from China’s Zhejang province accidentally spilled hydrofluoric acid, a toxic compound used to clean and texturize silicon wafers, into the adjacent section of the Mujiaquiao River. Because of this accident, hundreds of fish were killed and farmers near the location were greatly affected as they use the river to clean their animals.

Other Impacts

Once solar panels are created, they are transported and installed into homes, schools, businesses, and power plants. On the power plant scale, solar panel installations are often met with ecological challenges as it occupies massive land areas that can disrupt ecosystems. Solar panels have an estimated life span of 25 years, then they are removed and decommissioned. By 2050, the International Renewable Energy Agency (IREA) estimated that United States will generate 10M tons of cumulative solar panel waste.

Towards a Greener Solar

Several solar technological advancements reduce dependency on silicon. In search of a more efficient and sustainable material, organic solar cells (OSC) are being investigated to determine if it’s a feasible alternative for standard silicon cells. Comparing them with the 15-22% conversion efficiency of commercial solar cells, Lingxian Meng and his colleagues conducted a study which reported that OCSs reached 17% conversion efficiency. According to the U.S. Department of Energy, this technology has a theoretical potential of providing low-cost manufacturing, abundant material sources, and flexible substrates meaning it permits a wide variety of uses. Previously inefficient and nonviable for commercial production, these flexible, lightweight organic solar cells can now be potentially installed in car roofs, clothes, phone glasses, and windows.

On the other hand, the United States is leading the way in protecting the people and the environment from exposure to hazardous wastes from different processing facilities. EPA enforces the Resource Conservation and Recovery Act (RCRA) to impose strict requirements in safely handling, treatment, storage, and disposal of hazardous wastes. EPA also enforces the Toxic Substances Control Act (TSCA) that monitors already existing or new chemicals. Specifically, reporting, record-keeping, and testing are the requirements of TSCA for chemical importers and manufacturers. Ideally, nations around the world should impose strict environmental regulations on solar manufacturing facilities to ensure safety and avoid implications.

Solar technology will continue to evolve in the upcoming years. It is promising to see that studies report different innovation progress in making solar technology more efficient and sustainable. There is hope that the solar panel industry will become greener and greener in the years to come.

Sancho Cagulada is a graduate student in the Master of Landscape Architecture at Cal Poly Pomona. His interests revolve around participatory design and the integration of landscape architecture to transportation and industrial infrastructures.